12V, 24V or 48V – what’s the best voltage for your campervan electrical system?

Choosing the right DC system voltage for your off-grid electrical system is an important step in the design process, but how do you choose between 12V, 24V and 48V?

12V is the most common choice for campervan electrical systems, but why? Is it the same for boats and off-grid houses? And what are the advantages of using a higher system voltage? Will it be more expensive? Or harder to design?

In this article, we hope to answer all these questions to help you make the right decision for your off-grid electrical system.

What’s the difference between 12V vs 24V vs 48V?

When you design an electrical system, you need to decide on your main system voltage. The main system voltage is the voltage at which the battery bank will operate. And consequently, this will be the operating voltage of any components which take power into or out of the battery.

Choosing the best system voltage for you is one of many considerations you need to make when purchasing a battery bank. Our campervan leisure battery page takes a look at the rest of the factors you should consider before pulling the trigger.

A 12V electrical system is the most common choice for campervans, but for some, 24V or 48V can have some major advantages. Additionally, 24V and 48V are much more common in boats and off-grid houses. To understand the advantages of a higher system voltage, we first need to consider the relationship between voltage, current and power.

An important equation

The key to understanding this subject is in just one simple equation. The equation, called Watts Law, explains how electrical power is a product of both current and voltage:

P = I x V

P (measured in watts) is the amount of power used by an electrical load. For example, a fan might draw 20W and a hairdryer might draw 1500W.

I (measured in amps) is the current running through the wires.

V (measured in volts) is the voltage (sometimes called potential difference) generated by the power source. For example, a leisure battery might output 12V, 24V or 48V electricity.

A useful metaphor

To understand how these three parameters are related, we can visualise the electricity as a stream of water running down a pipe.

In this metaphor, the voltage is described by the height difference, giving the water ‘potential’ energy. The current is represented by the flow of water, i.e. a thin trickle, or a torrent. And finally, the power is depicted by how much energy the water has once it reaches the bottom. In other words, the resultant power is a product of the voltage and current combined.

Just like in the equation P = IV.

With this analogy in mind, we can now explain the difference between a 12V, 24V and 48V system. For instance, imagine the pipe is high (i.e. a high system voltage). The water has more potential energy, and therefore to achieve the same power production at the bottom of the pipe, we don’t need such a big flow of current.

Comparably, if the pipe is lower (i.e. a lower system voltage), the water has less potential energy, So, a larger flow of current is required to achieve the same power.

Example

Let’s say we need to draw 6000W of power from a 12V system. The resultant current through the wire will be:

I = P ÷ V = 6000W ÷ 12V = 500A

However, if we use 24V power, the current will be halved:

I = P ÷ V = 6000W ÷ 24V = 250A

In short, using a higher voltage means a smaller current runs through the wires and components. For this reason, we can choose components with a lower current rating. Most importantly, thinner cables and smaller fuses can be used.

Why do most people use 12V?

There is no definitive reason why 12V is so much more common than 24V or 48V, other than it’s been the industry standard for cars since the 1950s, and old habits die hard. And because it’s the most popular voltage to use, components such as leisure batteries, inverters and chargers are easy to find at 12V, but are less common at 24V and 48V. The same can be said for small electrical loads, like lights, fans and pumps.

When it comes to off-grid electrics in campervans and boats, 12V works well for the majority of people. In fact, out of all the customers we have designed systems for, 94% have used a 12V system, with only 4% using 24V, and 2% using 48V.

However, as technology improves and becomes more affordable, users want more and more from their electrical system. For example, many now want to power appliances such as AC units, induction hobs or electric heating. To do this, people need big batteries, big inverters, and systems capable of handling large currents. So, some systems will use 24V to help deliver those big power demands.

In addition, some users will even step up to 48V. Although, this is less common and more suited to off-grid houses, or boats with a 48V system already on board.

When should you use a higher system voltage?

For the majority of off-grid electrical systems, 12V power works great. So, when would you need to use 24V or 48V instead? There’s no exact rule to follow, but here are some reasons why you might step up to 24V or 48V.

You have high power requirements

If your system contains a 3000VA+ inverter or other high power appliances, then you should seriously consider 24V. Here, the higher system voltage results in a lower system current, which in turn allows you to use smaller wires and busbars.

A 3000VA inverter for example, will draw 375A when working at a 150% overload. As we want to allow this overload to deal with inrush current, we would spec a 400A fuse. This high current would require 120mm2 cable, which is both hard to work with and really expensive, at almost £30 per metre! You’d also definitely need a Lynx Distributor or a pair of 600A busbars to distribute this massive system current.

However, if you used a 24V system voltage instead, the current would drop down to 188A. Pairing this with a 200A fuse lets us use 35mm2 cable, which clocks in at a cool £8 per metre and is far easier to work with. Plus, you’ll be spending about half as much on busbars.

With high current in your system, the cost and availability of distribution and protection components might also be an issue. For example, MEGA fuses come in a variety of sizes, but the largest is rated to 500A. Additionally, 120mm2 is the largest readily available wire and is rated to just over 450A. So, for large systems with a potential system current larger than this, you’ll need to move to a higher voltage.

Please note: eBay and Amazon are full of poor quality cables and they are unlikely to have the same current capacity as the high performance wire that we use in our systems and sell in our webshop. The sellers on these platforms are also not qualified engineers, so don’t expect any technical support.

You have long distances to cover

When calculating the gauge of your cable, you need to consider the length of the cable. This is because of a phenomenon called voltage drop. Voltage drop in a wire is a product of its length, its resistance, and the current flowing through it.

Vdrop = Current (A) x Length (m) x Resistance (Ω/m)

The allowable voltage drop is often considered to be around 3%. As thicker cable has a lower resistance, the longer a cable is, the thicker it will need to be to maintain a voltage drop of under 3%.

Example

A 3000VA inverter is located 2m away from a 12V battery bank, and has a 4m ‘there and back again’ circuit length. It’s connected to the battery bank with 70mm2 cable, which has a resistance of 0.00027 Ω/m. So:

Vdrop = 250A x 4m x 0.00027 Ω/m = 0.3259V

0.3259 ÷ 12 = 2.7% voltage drop

However, if the cable length increased to 4m, so an 8m ‘there and back again’ circuit length, the voltage drop would increase.

Vdrop = 250A x 4m x 0.00027 Ω/m = 0.6519V

0.6519 ÷ 12 = 5.4% voltage drop

Even if we increased the cable gauge to 120mm2 which has a resistance of 0.00015 Ω/m, this would still be over the allowable voltage drop of 3%.

Vdrop = 250A x 8m x 0.00015 Ω/m = 0.3669V

0.3669 ÷ 12 = 3.1% voltage drop

If long cable lengths in your system mean that even 120mm2 cable is too thin, you may look to increase your system voltage to 24V or 48V.

Long wire lengths are more likely to be an issue in boats, where cables may need to travel the length of the hull to power loads with a high current draw, such as motors and pumps.

You already have 24V or 48V appliances

If you have a hybrid or electric boat, you may already have a 24V or 48V electric motor on board. Or, you might have a 24V heater for your campervan. In these instances, it may make sense for your system voltage to also be 24V or 48V to avoid needing to step up to this voltage to run certain appliances.

However, if you have any 12V appliances to run such as lights or fridges, then if you have a 24V or 48V system you will need to step back down to 12V. So, in this case it’s important to consider which option makes most sense for you.

You have a 24V or 48V starter battery

Some boats and larger vehicles such as old Varios may have a 24V or even 48V starter battery. It’s possible to purchase a 24V to 12V battery to battery charger, so this doesn’t necessary mean that your whole system voltage should be 24V. But it should be a consideration – if you have a 24V starter battery and a 24V heater, or a 24V starter battery and larger power requirements – then it might start to make sense to pick 24V as your system voltage.

Ultimately, there are a lot of factors to consider when choosing your DC system voltage. Whilst some factors will definitely mean an increase in DC voltage is required, other factors may not, so you should make to consider everything before choosing whether 12V, 24V or 48V is right for you.

Campervan electrics leaving you confused?

How to wire a 24V or 48V electrical system

If you want to use a 24V or 48V DC system voltage, the basic principles of designing your an off-grid electric system will be the same. However, there are a few things you’ll need to take into account.

To begin with, most of the electrical devices connected to the battery bank will need to operate at the correct voltage. This is always specified when you buy the device and is easy to get right.

Whilst inverters and battery to battery chargers have specific 12V, 24V and 48V models, most of the Victron solar charge controllers can detect the voltage of your batteries. By connecting the controller to your batteries before your solar panels, the unit detects the battery voltage so it knows what voltage to output for your system.

If your starter battery (and alternator) operates at a different voltage to your leisure battery, the correct B2B charger can be used to convert the voltage. This means you’ll still be able to charge your leisure battery bank from the power of the engine.

Finally, if you still want to power some 12V loads (such as lights, fans, or water pumps), you’ll need to create a 12V sub-system. This is easily done, using a DC-DC converter. The 12V power can then be distributed with a 12V fuse board, which is separate from your 24V fuse board.

The diagram below describes how power will flow through a typical off-grid electrical system, where the main system voltage is 24V, the starter battery is 12V, and there are two separate fuse boards.

Different parts of an off-grid electrical system can operate at different voltages

Differences between a 12V vs 24V vs 48V system

If you choose to work with a higher battery voltage, most of your system will work in exactly the same way. However, you will need to ensure your components are all specced to the correct voltage. And there will be some differences in the design of your system.

To help break it down, here’s a description of each system component, from the batteries to fuses, with a direct comparison between 12V and 24V. We’ve also considered the cost implications of each sub-system, to demonstrate which parts get cheaper, and which don’t really change.

12V vs 24V battery banks

When comparing leisure batteries, the number of watt hours (Wh) is the best indicator to describe how much energy a battery can store. You might be used to looking at amp hours (Ah), but the watt hours can be directly compared between batteries of different voltages.

Each of these batteries has the same Wh capacity, even though their voltage and Ah are different

When it comes to cost, batteries of a higher voltage aren’t significantly more expensive (per watt hour). In other words, the three batteries above would be similar in cost because they all have the same capacity in watt hours.

For example, we can compare three batteries, which are all of different voltages, and of different Wh capacities.

| Voltage | Capacity (Ah) | Capacity (Wh) | Price | Price per kWh |

|---|---|---|---|---|

| 12V | 216 | 2592 | £1,429.00 | £551 |

| 24V | 150 | 3600 | £1,995.00 | £554 |

| 48V | 100 | 4800 | £2,737.00 | £570 |

However, prices will still vary between brands, and between batteries with slightly different features. And you will find that you have fewer choices when browsing for 24V or 48V batteries. Because of this lack of variety, you’ll have fewer options when it comes to size, type, and price.

For this reason, you might end up spending more on a 24V or 48V battery, simply due to the lack of choice when buying.

If you are struggling to find affordable 24V or 48V leisure batteries, you can use 12V batteries instead. 12V leisure batteries can be wired together in series to create a 24V or even 48V system.

For example, to create a 24V battery bank, there are two options:

- Use two or more 24V leisure batteries connected in parallel (or just one)

- Connect two 12V batteries in series

When you connect two batteries in series, you add together the voltage and the amp hour rating stays the same. When you connect two batteries in parallel, the voltage stays the same and you add together the amp hour rating and the voltage stays the same.

So, if you had two 100Ah 12V batteries wired in series, you would create a 24V 100Ah battery bank. In comparison, if you had two 100Ah 24V batteries wired in parallel, you would create a 24V 200Ah battery bank.

A similar technique can be used to create a 48V system voltage using 12V batteries. Find out more about wiring 24V or 48V leisure batteries further down in this article.

12V vs 24V inverters

An inverter takes DC power and converts it into AC power at mains voltage (230V in Europe, 120V in US). Whichever voltage you choose for your leisure battery, you’ll need to choose an inverter to match that input voltage. Luckily, this is unlikely to affect the cost of the inverter. For example, there’s only a ~£10 price difference between the Victron 800VA inverter 12V and 24V models.

If you want to charge your leisure battery from shore power, you might need a combined inverter/charger. In this case, there may be a small difference in price. For example, here’s the difference in price between 12V, 24V, and 48V Victron inverter/chargers, all rated to output 3000VA.

12V vs 24V battery to battery chargers

To charge a leisure battery from the alternator, a battery to battery charger can be used, which comes in a variety of voltage options. For example, different models of the Victron Orion DC-DC charger can convert between 12V, 24V or 48V DC power. This makes it easy to choose the right B2B based on the voltage of your alternator and your leisure battery.

If you’re using 48V for your system voltage, you’ll need to make sure your engine’s alternator is either 24V or 48V. Unfortunately, a single product isn’t available to charge a 48V battery from a 12V alternator.

However, it is possible to use two 12/24 battery to battery chargers with the outputs wired in series to achieve the desired 12v input and 48V output.

DC-DC converters

Regardless of your main system voltage, it’s more than likely that your system will still use 12V products and appliances. For this reason, it’s wise to provide provision for 12V loads in your system design.

Not to be confused with battery to battery chargers (they often look the same), DC-DC converters can be used to power loads which need a different voltage from your battery voltage.

For example, if you have various 24V loads but your leisure battery is 12V, you can use a 12V-24V DC-DC converter to convert the system voltage from 12V to 24V. Conversely, if you’ve chosen 24V as your main system voltage, you’ll need a 24V-12V converter to power any 12V loads.

Your next consideration is achieving adequate current to power your 12V loads. Between 30A and 60A is typically sufficient for most people, however you should calculate the combined current draw of all of your 12V appliances, and then add a factor of safety to this number. Unlike battery to battery chargers, DC-DC converters aim to provide on demand power to loads up to a defined current, opposed to utilising clever charging profiles to bring your battery bank up to full charge.

12V vs 24V solar charge controllers

When choosing a charge controller, you’ll need to look out for four different specifications:

- The maximum input voltage from the solar array

- The current rating of the solar array

- The maximum wattage of the solar array

- The output voltage (i.e. the voltage of your battery bank)

The voltage of the solar array will depend on the voltage of each panel and how they are wired together. Thankfully, the voltage of the solar array doesn’t have to match that of your battery bank. This is because the charge controller is designed to convert the input voltage from the solar panels into the correct output voltage to charge the battery.

Most MPPT charge controllers (including Victron’s SmartSolar charge controllers) have an automatic voltage detect function which will automatically match the system voltage, whether that’s 12V, 24V or 48V. As a result, changing your system voltage won’t directly affect the cost of the charge controller.

Bear in mind, there are still some models which don’t cover 48V, so check the specifications for each before you buy. At the time of writing, the 100/30 and 100/50 MPPT charge controllers are not 48V compatible.

It’s also important to remember that you won’t be able to charge a battery from a solar array with a lower nominal voltage. For example, a 12V solar panel can’t charge a 24V battery bank. However, 24V and 48V solar panels are readily available, and you can even create a 24V or 48V solar array by connecting multiple 12V panels in series.

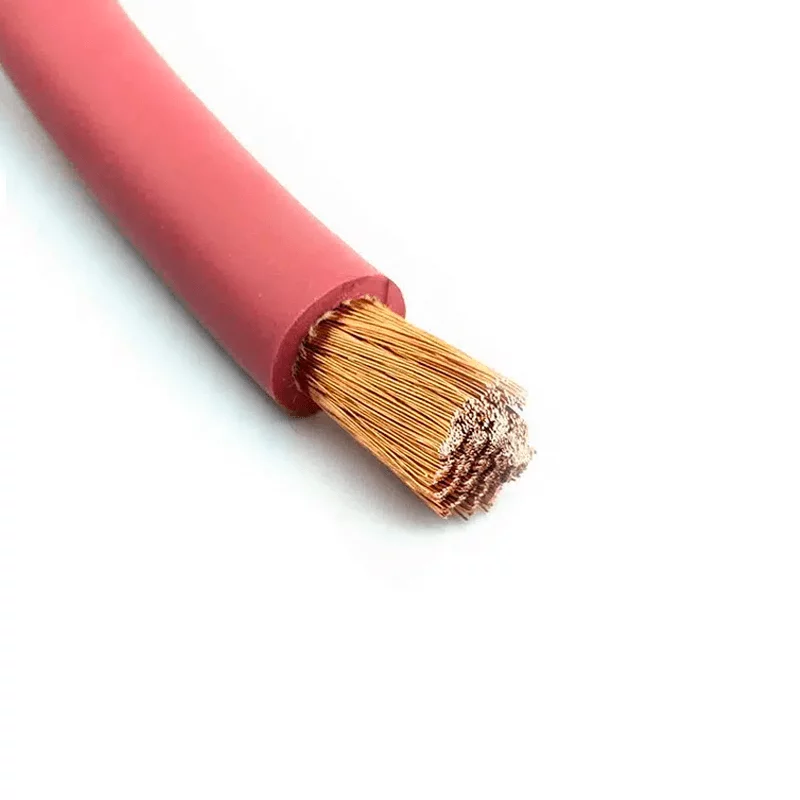

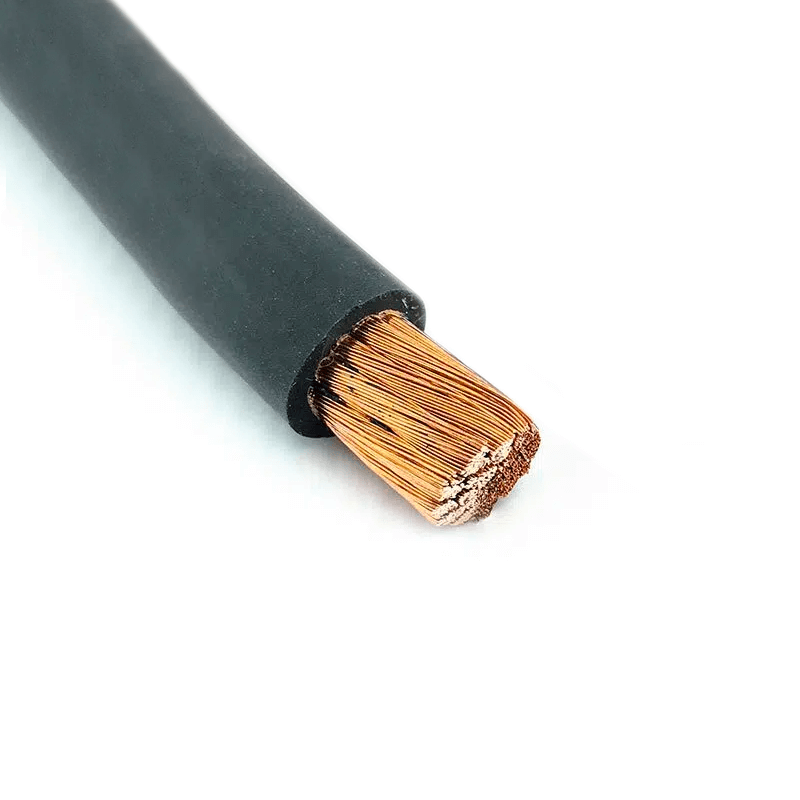

Cable gauge – 12V vs 24V

Cable gauge is the most obvious component that changes between 12V, 24V and 48V systems, and it’s often the main reason for stepping up to 24V or 48V. To understand why, let’s explain how the thickness of your cables can change when you use a different DC system voltage.

How does the system voltage affect cable gauge?

Choosing the right cable gauge is a little bit like choosing the right pipe size for a stream of water. The ‘pipe’ must be large enough to allow the electrical current to pass through without too much resistance. If the cable is too small, the resistance will be high, and the temperature inside the cable will rise. High temperatures lead to melted wires, and can therefore be a big fire risk.

Cable too small → high resistance → high temperatures → fire risk

In addition to this, the length of wire also has an effect on the required cable gauge. The longer the cable, the more opportunity for energy loss due to resistance. Therefore, significant voltage drop can occur. For this reason, you’ll need to increase the cable gauge even further for longer cable lengths.

When you use a higher system voltage, the electrical current which needs to pass through the wires will be proportionally smaller. Therefore, the cables you use can also be smaller.

For larger cable gauges, the cost per metre can really start to add up, especially if you need to cover a lot of distance. For this reason, using a higher system voltage will save you some money on electrical cable.

Which cables will change with a higher system voltage?

Any part of your system which uses the same voltage as your batteries (i.e. hasn’t been converted to a higher or lower voltage by a DC-DC converter) can be sized according to your system voltage. For example, in a system using 24V, the cable connecting the inverter to the busbar will be thinner than in a system using 12V. However, the difference in cost will be most significant in long cables which carry high currents.

For example, the cables running from the battery to the inverter are often the thickest cables in an electrical system. So, if you need to run high-power 230V loads, you might need to use a higher system voltage, especially if the inverter is far from your battery bank. Where a 3000VA 12V inverter will require 70mm2 DC cable over a 4m ‘there and back again’ length, a 3000VA 24V inverter will only require 25mm2 DC cable.

Any parts of the system that have been converted to run on a different voltage, such as a 12V system powered by a DC-DC converter, will need to be calculated using 12V rather than 24V or 48V. Similarly, the solar panel cables won’t change either, since the solar system voltage is independent from the battery voltage. Solar panel cables should be calculated based on the voltage of the solar panels rather than the voltage of the system.

What’s cheaper, a 12V or a 24V system?

Answering whether a 12V or a 24V system is cheaper isn’t black or white. This is because every system is different, and the lengths and size of cables will vary massively. However, below we will go through two very simplified, theoretical examples. Hopefully, this will demonstrate how a higher system voltage is beneficial for some systems, but not for others.

Example 1

Let’s consider a 12V electrical system with high power requirements, where long lengths of cable are needed to connect some of the main components.

Let’s say the system has a total current draw of 350A, and an inverter drawing 250A. So, it requires 95mm² cable for the batteries which are 2m away from the busbars (4m ‘there and back again’ length), and 95mm² cable for the inverter, which is 3m away from the busbars (6m ‘there and back again’ length).

Cost of cable (12V system voltage):

95mm² cable x 10m = £287.10

Total = £287.10

Now, suppose we used a 24V system voltage instead. This means the overall current draw for the system is now 175A and the inverter draws 125A. The system cable can decrease to 35mm² and the inverter cable can decrease to 25mm².

Cost of cable (24V system voltage):

35mm² cable x 6m = £58.20

25mm² cable x 4m = £27.68

Total = £85.88

Here, we can see that by increasing the system voltage, there is a cost saving of £201.22. However, to power your 12V appliances you will need to use a 24V to 12V DC-DC converter. The cost of the Victron Orion 24/12-70 Non-isolated DC-DC Converter is £136.28.

So, for this example, the total you would save £64.94.

Example 2

Now let’s consider a 12V electrical system with low power requirements, where only short lengths of cable are needed to connect the main components.

Let’s say the system has a total current draw of 150A, and an inverter drawing 42A. So, it requires 35mm² cable for the batteries which are 1.5m away from the busbars (3m ‘there and back again’ length), and 10mm² cable for the inverter, which is 1.5m away from the busbars (3m ‘there and back again’ length).

For example, let’s say we need 3m of 70mm², and 8m of 6mm².

Cost of cable:

35mm² x 3m = £29.10

10mm² x 3m = £15.27

Total = £44.37

Now, suppose we use a 24V system voltage instead. This means the overall current draw for the system is now 75A and the inverter draws 21A. The system cable can decrease to 16mm² and the inverter cable can decrease to 3mm².

Cost of cable (24V system voltage):

16mm² x 3m = £13.29

3mm² x 3m = £2.07

Total = £15.36

In this case, the difference in price is only £29.01. Once we factor in the cost of the 12/24 DC-DC converter, this system will be more expensive.

For this example, the 24V system is £107.27 more expensive than the 12V system.

To conclude, significant savings will only be made if your system calls for long lengths of very thick cable.

Fuse rating – 12V vs 24V

In every electrical system, high current spikes can cause damage to wiring and circuitry. Therefore, fuses are used to protect components, sub-systems, and the system as a whole. They are designed to blow at a predefined current, which breaks the circuit and stops the flow of electricity.

The rating of a fuse is the current at which it is designed to blow. Therefore, when choosing a fuse, it should be somewhere between the current expected to flow under ‘normal conditions’ and the current which will damage the wires or circuitry.

It’s important to note that 48V systems require special fuses as most MEGA fuses and MIDI fuses are only rated up to 36V. The voltage rating of a fuse determines the maximum voltage at which the fuse can safely interrupt an abnormal current and prevent arcing between the gap of the blown fuse. Because 48V fuses (often referred to as 58V fuses) are less common, they typically cost a lot more than those rated for up to 36V systems.

12V vs 24V fuse boards

If you want to power 12V and 24V loads, such as lights, fans or pumps, you’ll need two separate fuse boards to distribute the power safely. A good-quality 12V or 24V fuse box costs around £60. Don’t forget – you’ll also need a DC-DC converter to create the change in voltage.

Busbar rating – 12V vs 24V

The busbar is another component which should be chosen based on the maximum current in your system. Therefore, once again, a smaller busbar can be used when the system voltage is higher.

For example, if a 12V system had a maximum current of 450A, it would need a 600A busbar (the nearest standard size above 450A). However, if the system operated on 24V instead, the maximum current would drop to 225A. Consequently, a 250A busbar could be used instead. This would save around £110 in total, between the two busbars.

2 x 600A busbars = £218

2 x 250A busbars = £108

Difference in price = £110

You can read more about busbars in our Lynx Distributor article.

System switches – 12V vs 24V

If your 12V system has high power requirements, you may have to use a very large system switch. If your system current is more than 300A, you will need to use a ‘heavy duty’ switch rated to 600A. In comparison, if you opt for a 24V system, this will decrease the switch rating you require, which will save you money.

For example, a 12V system with a continuous current of 500A (not recommended) would need to use a 600A switch. Alternatively, if a 24V system voltage was used, the system current would decrease to 250A, so the 300A switch could be used instead.

1 x 600A switch = £104

1 x 300A switch = £35

Difference in price = £69

For most DIY converters, we recommend the 300A Blue Sea Systems Mini On/Off Battery Switch. In some instances, someone might question why the fuse rating is actually higher than the switch it sits next to. This is because the fuse is protecting against current spikes, but the switch is chosen based on the normal operating current. The 300A Blue Sea switch can withstand current spikes of 500A for up to 5 minutes and 900A for up to 30 seconds.

Cost implications of DC system voltage

Now that we’ve talked about each individual part of the system, we can weigh up the pros and cons of a higher system voltage, and see where the savings can be made.

With a higher system voltage, components such as cable, fuses (unless you need 48V fuses), busbars and switches will all be smaller and cheaper. However, we’ve seen above that the difference in cost is pretty insignificant unless your system has some really high power requirements.

Other than that, there aren’t any big savings to be made with a higher system voltage. For instance, there won’t be much difference in price between the main components, such as batteries, inverters, or B2B chargers. And you’ll actually have to spend a little more on a DC-DC converter and an extra fuse board.

In addition to this, the house loads themselves can also be more expensive and more difficult to source in 24V or 48V (e.g. lights, fans, pumps, etc.). Since 12V is the most popular voltage, economies of scale and market competition keep prices down.

The final cost difference will ultimately be dependent on your individual system, but in reality, it’s likely to be fairly small in either direction. At the end of the day, your decision about DC system voltage should be based on practical reasons, rather than cost.

Campervan electrics leaving you confused?

DC system voltage – FAQs

-

Technically, using a higher voltage does result in less energy lost due to resistance. Energy loss occurs in wires when the current experiences a resistance, which generates heat, resulting in wasted energy. Using a higher system voltage means lower current, and therefore less heat loss.

However, if you don’t have very high current and you use the correct cable gauge, this energy loss should be very very small and almost negligible. And even with a high system current at 12V, it will only be inefficient if the cables aren’t thick enough, causing unnecessary resistance.

In addition, you might also consider the energy lost through the DC-DC converter, which powers the 12V loads. For example, most DC-DC converters will have an efficiency of around 90%. Therefore, even if there is less electrical resistance in a 24V system, you’ll still lose another 10% of all the energy used to power the 12V loads.

-

A 24V system is only ‘better’ than a 12V system if it’s the right choice for your application. A 24V system will only benefit people with big power demands or long cable lengths. If you’re not in this category, you’ll likely end up spending more money and have a more complex system, for only a very small change in efficiency.

-

If you’re still not sure which voltage might work best for your own system, here’s some general guidance to help you decide:

- If your power demands are below 3000W, choose a 12V system

- If your power demands are between 2000W to 5000W, a 24V system might be suitable (based on other considerations)

- If your power demands are over 4000W, then a 48V system might be most appropriate

This guidance might seem a bit vague, since there’s a lot of overlap, but that’s because there is no definitive answer to this problem. If you fall between two categories, it’s likely that either voltage will do the job, with some pros and cons to each choice.

In reality, there’s no real issue with using a higher voltage than you actually need. You might just find it harder to source some components, and you’ll probably end up spending a bit more on your system than is really necessary.

-

As long as cables, fuses and other components are specified correctly for your system voltage, then a 24V system is no safer than a 12V system.

There are two aspects to consider when thinking about electrical safety: fire hazard and electric shock.

Fire hazard

When it comes to fire hazard, there is an argument that larger current in a system with a lower voltage leads to an increased fire risk. However, this isn’t really the case. Yes, a higher voltage means a smaller current, but there is still an inherent risk with either system. In reality, the wires, fuses and switches should all be specced correctly to avoid fire risk, regardless of the system voltage.

Electric shock

To consider the effect of electricity on the human body, you need to consider both current and voltage. Technically, it is the current which causes damage to the body, such as burns, freezing muscles, or fibrillating the heart. However, the current which flows will be determined by the voltage of the power source and the resistance.

P = I x V

In this equation, the resistance value will vary massively from person to person, and with the type of contact which is made. For example, a wire touched with a dry finger will have a very high resistance, but contact with a wet palm will have a much lower resistance, allowing more current to flow into your body.

From this equation, we can also see that a larger voltage provides more energy to push that current through the body. In other words, a higher voltage is, technically, more dangerous than a lower voltage.

However, the human body has an inherently high resistance to the flow of electric current. Therefore, these low DC voltages still have the potential to cause harm but are generally considered safe to work with. In fact, the International Electrotechnical Commission defines 50V as the threshold DC voltage, below which the current would be too low to provide a lethal electric shock.

Therefore, although any voltage can be dangerous if the conditions are right, the difference in safety between 12V, 24V or 48V shouldn’t be a factor when you’re choosing your DC system voltage.

-

Even if a vehicle has a 24V starter battery (which is common in very large vans, LGV’s and some boats), this doesn’t mean that the rest of the system must also be 24V. DC-DC converters are available which convert 24V to 12V. Therefore, you can still achieve alternator charging, even if the batteries operate at different voltages.

This should only affect your choice of system voltage if it’s one of a few considerations pointing towards a higher system voltage. For example, if you have a 24V starter battery and you have 24V appliances such as a 24V heater, then it might make sense to opt for a 24V system.

-

To achieve a 24V system voltage, multiple 24V batteries can be wired together in parallel. When batteries are wired together in parallel, the voltage across them remains the same. This method is often used to achieve a bigger capacity which can’t be met with just one battery. The total capacity of the bank in watt hours will be the sum of each battery’s capacity.

To connect 2 x 24V batteries in parallel, the following configuration can be used:

The following configuration can be used to connect 4 x 24V batteries in parallel:

This layout might seem overly complex, but it ensures each battery is charged and discharged evenly. Without perfectly balanced charging, some batteries will degrade faster than others, creating imbalance in your system.

It is possible to connect three batteries together in parallel with the configuration below, but you won’t be able to achieve perfectly balanced charging.

-

Another way to create a 24V system is to connect 2 x 12V batteries in series. When batteries are wired in series, the resultant voltage will be the sum of the two battery voltages.

To connect two batteries in series, simply connect the opposite terminals, then use the other free terminals as your positive and negative connections.

The same technique can be used to create a 48V system from two 24V batteries.

-

If you need even more battery capacity, you can wire four 12V batteries together to achieve a 24V system voltage. This is achieved by connecting two pairs of series-wired batteries, like in the diagram below. This is called series-parallel.

Hello, very detailled guide. Thank you. One question please : I have two 12V 200Ah lithium batteries that I would like to wire for 24V, what Orion should I buy to charge’em from the alternator ? The 12/12 version or 12/24 ? Thank you

We’re glad you found it useful, if you fill out this form here one of our engineers will be happy to help you choose your DC/DC charger and with any other questions you might have!

This was great! Well written. I now feel a tiny bit closer to being an electrical engineer. Thanks! 😀