Victron Lynx Distributor – do you need one in your electrical system?

What is the Victron Lynx Distributor?

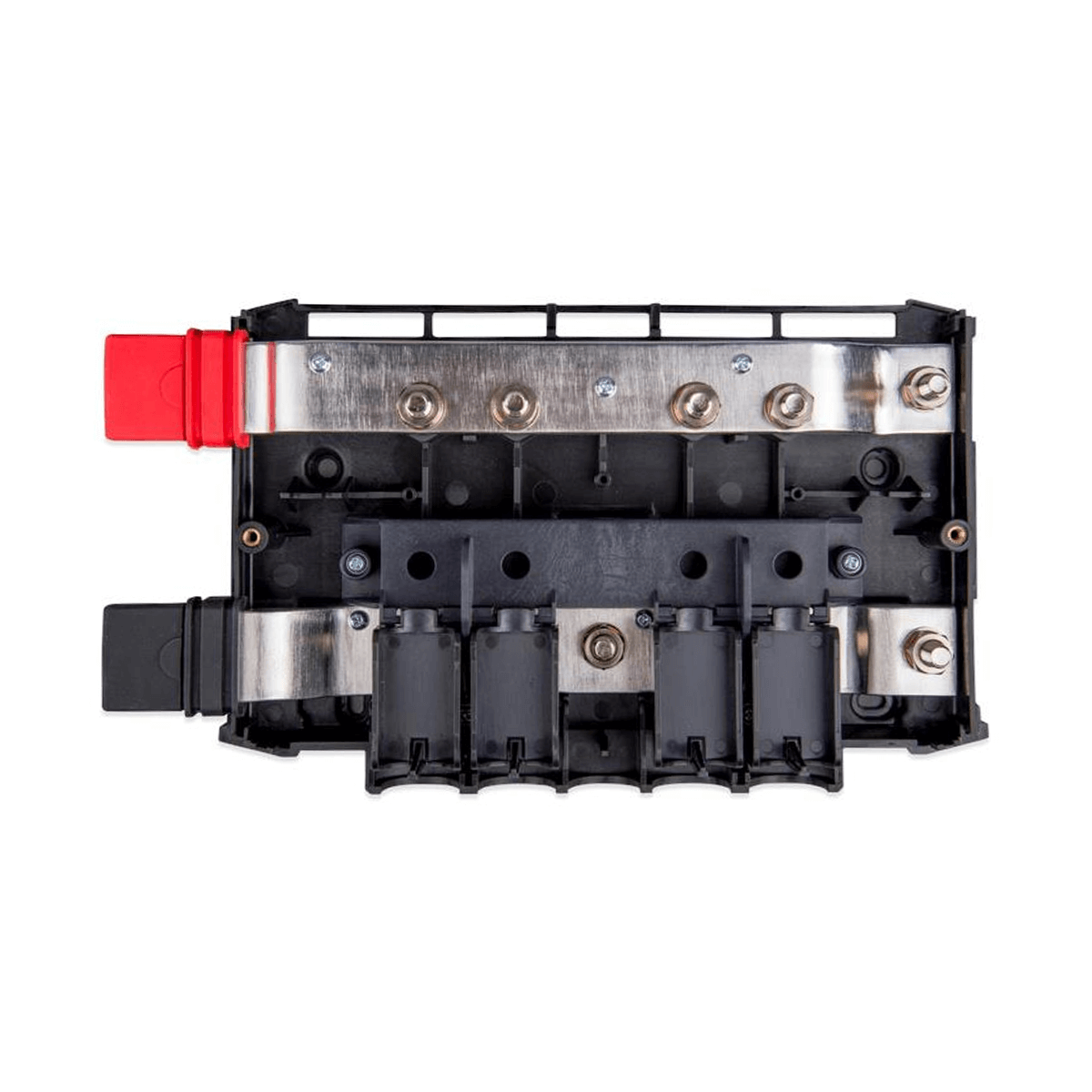

The Victron Lynx Distributor is a modular DC busbar unit rated to 1000A. It’s made up of a positive busbar, a negative busbar and four MEGA fuse holders. It offers a compact all-in-one solution for connecting various sub-systems in your electrical system (e.g. solar arrays, inverters, DC-DC chargers) to your leisure batteries.

If you connect the Lynx Distributor to a Lynx Shunt or Lynx Smart BMS, an LED will light to indicate a blown fuse and a notification will be sent to the Victron Connect app (Smart BMS only).

Whilst it provides a cost-effective option for those with large power requirements, the 1000A current rating may be overkill for many. Additionally, only being able to use MEGA fuses may be limiting.

This article will cover what the Victron Lynx Distributor is, whether you need one and what other options exist. We’ll also take a look at the other components in the Lynx ecosystem and give examples of how to install one within your electrical system.

What is a busbar and why do I need one?

Busbars act as a common point in your circuit for connecting cables to. They consolidate all the connections to the battery bank for a secure, low-resistance connection. For this reason, a campervan electrical system should have a busbar attached to both the positive and negative sides of the battery bank.

To avoid purchasing busbars, some people try to fix all positive and negative connections directly to the battery. This is a bad idea for multiple reasons.

High contact resistance

Firstly, the physical difficulty of trying to mount more than two cable lugs onto a battery terminal makes it extremely difficult to make secure connections. It will likely result in cable lugs being attached to the battery via other cable lugs, resulting in high contact resistance.

High contact resistance occurs where two conductors meet. A metal’s surface is imperfect, and irregularities and oxidation mean a less than perfect area of metal-to-metal contact. Consequently, there is a higher resistance between two contacting conductors than elsewhere in the conductor. As tin is less prone to oxidation, copper lugs, busbars and other connections are often tin plated to reduce the contact resistance. However, this is not a perfect solution, and contact resistance is still inevitable.

High resistance means a high voltage drop over the connection, and therefore a high power dissipation in the form of heat. This can quickly cause your system to overheat! Stacking lugs is generally okay for a few low-power connections, but too many will increase the contact resistance. Moreover, the cable lugs will likely only be rated for their respective load’s current draw, and not the current draw of several stacked connections.

Lots of vibrations

Secondly, consider that when in transit, a van is constantly vibrating. The more parts a connection has, the more likely one loosens. A loose connection has a lower contact area and consequently, a higher resistance. By securing each connection individually to a busbar, the contact resistance is small and consistent. Moreover, the current flow is spread over the volume of the busbar, not through a cable lug! Just make sure the busbar’s current capacity (how much current draw it can handle) is sufficient for your circuit.

You need a battery protection fuse

Finally, you need to include a fuse between each sub-system and your battery. Fuses are designed to blow in the case of a current surge, therefore breaking the circuit and protecting the batteries, as well as connected components and cables. Accordingly, you should rate them higher than the peak current draw of the circuit that they’re protecting, but lower than the rating of the cable they’re connected to.

In a system without busbars, you would have to fuse each load close to the battery to protect it. This is because any short circuits that occur before the fuse would damage the battery. So, the distance between the fuses and the battery should be as short as possible.

This is much easier to achieve if you connect all of your sub-systems to a busbar. You can then include just one battery protection fuse between the busbar and the battery. Subsequently, you can place the fuses for each load elsewhere along the connection. The result is a more organised system with fewer fuses mounted next to the battery.

What size busbar do I need?

You should size busbars in the same way as any other current carrying component (e.g. cables), by ensuring that the highest current they can carry is less than their current capacity. Additionally, the voltage drop should remain low. Aim for a voltage drop less than 3% over the whole circuit.

When rating busbars, manufactures consider numerous factors. This includes the temperature they reach under load. Therefore, it’s difficult to calculate the required busbar based on its dimensions. For this reason, we recommend adding a buffer to your maximum system current, and choosing a busbar with a current rating larger than this.

Do I need a Lynx Distributor in my electrical system?

You can use the Victron Lynx Distributor as a replacement to a positive and negative busbar, and several fuses and fuse holders. It’s suitable for high power systems as it’s rated to 1000A. Let’s take a look at a few factors to help you decide if you need a Lynx Distributor in your electrical system.

It helps you to design a neat and tidy electrical system

In lower spec systems, a Victron Lynx Distributor introduces an additional cost. Regardless, for many, its compact size and modularity is worth the price. Often, electrical systems have to fit in a small area (e.g. over a wheel arch). Here, the space efficiency of the Lynx Distributor is valuable.

After a sustained or high current flow, busbars heat up significantly. So, in most systems, you should mount busbars apart and route wires in opposite directions. This is because a cable touching a hot busbar could melt and potentially cause a short circuit.

To avoid this, the Lynx Distributor contains insulated cable guides. These route cables to the positive busbar over the negative busbar, and the positive and negative cables stack. In effect, you can route all cables out of one side of the Lynx Distributor. This results in an efficient and organised system, which in itself makes the Distributor worth it for many.

The diagrams below show the increased space efficiency of using a Lynx Distributor over separate busbars and fuse holders.

For some, the way in which the Victron Lynx Distributor fits with the rest of the Lynx ecosystem is desirable. If you look to purchase any other product in the Lynx series, their modularity makes the Lynx Distributor a solid choice. Furthermore, multiple Lynx Distributors can bolt together for a seamless busbar extension.

Additionally, by connecting to the Lynx with the VictronConnect app, you can monitor the fuse status from your phone. However, this is only possible if the Lynx Distributor is paired with a Lynx Smart BMS, a luxury only reserved for those investing in Victron Smart lithium batteries.

It depends on your electrical system use case

The Victron Lynx Distributor and individual busbars from Blue Sea or Victron have been designed with a different target audience in mind. Looking at the product specifications for several busbars from each company, it’s clear that the Lynx Distributor is an outlier when it comes to busbar cross-sectional area. Below is a comparison of different busbar current ratings and their cross-sections. All of these busbars are made from tin-plated copper.

| Brand | Current rating (A) | Cross-section (mm2) |

|---|---|---|

| Victron | 250 | 120 |

| Victron | 600 | 456 |

| Victron | 1000 (Lynx Distributor) | 240 |

| Blue Sea | 250 | 164 |

| Blue Sea | 600 | 485 |

| Blue Sea | 1000 | 926 |

The 250A and 600A busbars from each company have similar cross-sections. Conversely, the Lynx Distributor’s busbars are just under a quarter of the thickness of Blue Sea’s 1000A busbar.

At first glance, it’s hard to understand why Victron would include a busbar that’s so much thinner than their 600A model in a product rated to 1000A. Initially, you may think that one is either under or over specced. However, it’s more likely that they have just been rated for a different use case.

Blue Sea Systems design components primarily for marine and industrial applications. Because of this, their products have to withstand very testing environments. This includes the high temperatures and sustained vibrations of an engine room.

Comparatively, Victron design products for off-grid enthusiasts working on vans, off-grid houses and domestic boats.

Whilst having to keep the same reliability, the conditions each component needs to face are different. This likely explains the difference in specifications between the two 1000A rated busbars. Victron intended their standalone busbars to provide an alternative to Blue Sea’s offering, that can be used in the same environments. So, they require similar specifications.

By creating a new all in one system, Victron have been able to cater for their own target audience and spec the Lynx accordingly.

It depends on the cost difference

We’ll consider two example electrical systems with different power requirements to show when using a Lynx Distributor is the more cost-effective option.

Example 1

Let’s consider a mid-power system with a 1200VA inverter/charger and a 200A maximum system current. For its power distribution, the system would need:

- 2x 250A busbars = £113.54

- 4x Victron MEGA fuse holders = £48.64

- 4x MEGA fuses = £17.60

Total = £179.78

If this system used a Lynx Distributor for its power distribution, it would need:

- Lynx Distributor = £213.89

- 4x MEGA fuses = £17.60

Total = £231.49

So, it would be £51.71 cheaper to use the individual busbars and MEGA fuse holders.

Example 2

Let’s consider a high-power system with a 3000VA inverter/charger and a 350A maximum system current. For its power distribution, the system would need:

- 2x 600A busbars = £229.18

- 4x Victron MEGA fuse holders = £48.64

- 4x MEGA fuses = £17.60

Total = £295.42

If this system used a Lynx Distributor for its power distribution, it would need:

- Lynx Distributor = £213.89

- 4x MEGA fuses = £17.60

Total = £231.49

So, it would be £63.93 cheaper to use the Lynx Distributor in this example.

From these costs, we can see that if your system uses 150A or 250A busbar, it isn’t as cost-effective to use a Victron Lynx Distributor. We typically only recommend using one when speccing systems with an inverter or inverter/charger 3000VA or larger. Lower power systems are also more likely to require a fuse smaller than that of the MEGA range, which can cause problems – read on for these!

Because of its premium cost, it only becomes cost-effective to invest in a Lynx Distributor if your current draw surpasses 250A. This is because, when compared to purchasing 600A or 1000A busbars and individual fuse holders, the Lynx Distributor is cheaper.

Limitations of the Lynx Distributor

Although a very capable product, the Victron Lynx Distributor is not for everyone. Here are some limitations to consider when speccing your system.

It only holds four fuses

Many campervan electrical systems include the following four sub-systems connected to the battery bank:

- Inverter or inverter/charger – for 230V loads

- Solar array – including solar panels and solar charge controller

- Battery to battery charger(s)

- 12V fuse box – for 12V loads

So for most, the four positive and negative terminals on the Lynx Distributor are enough. However, some systems that contain multiple solar arrays, for example, may require additional busbar connections.

A solution is to connect both charge controllers to a single terminal on the Distributor. It’s fine to do this as the cable gauges will be relatively small, both charge controllers would just need accounting for when sizing the MEGA fuse. It’s acceptable to stack a few lugs on a terminal, but this should be kept to a minimum. You should also size them correctly by accounting for the combined current draw.

In some cases, you might need to make five or more individual connections. A simple but expensive solution to this problem is to just add a second Lynx Distributor! You can bolt together the busbar ends to double the available terminals. Note that Victron states that you can fix up to four Distributors together.

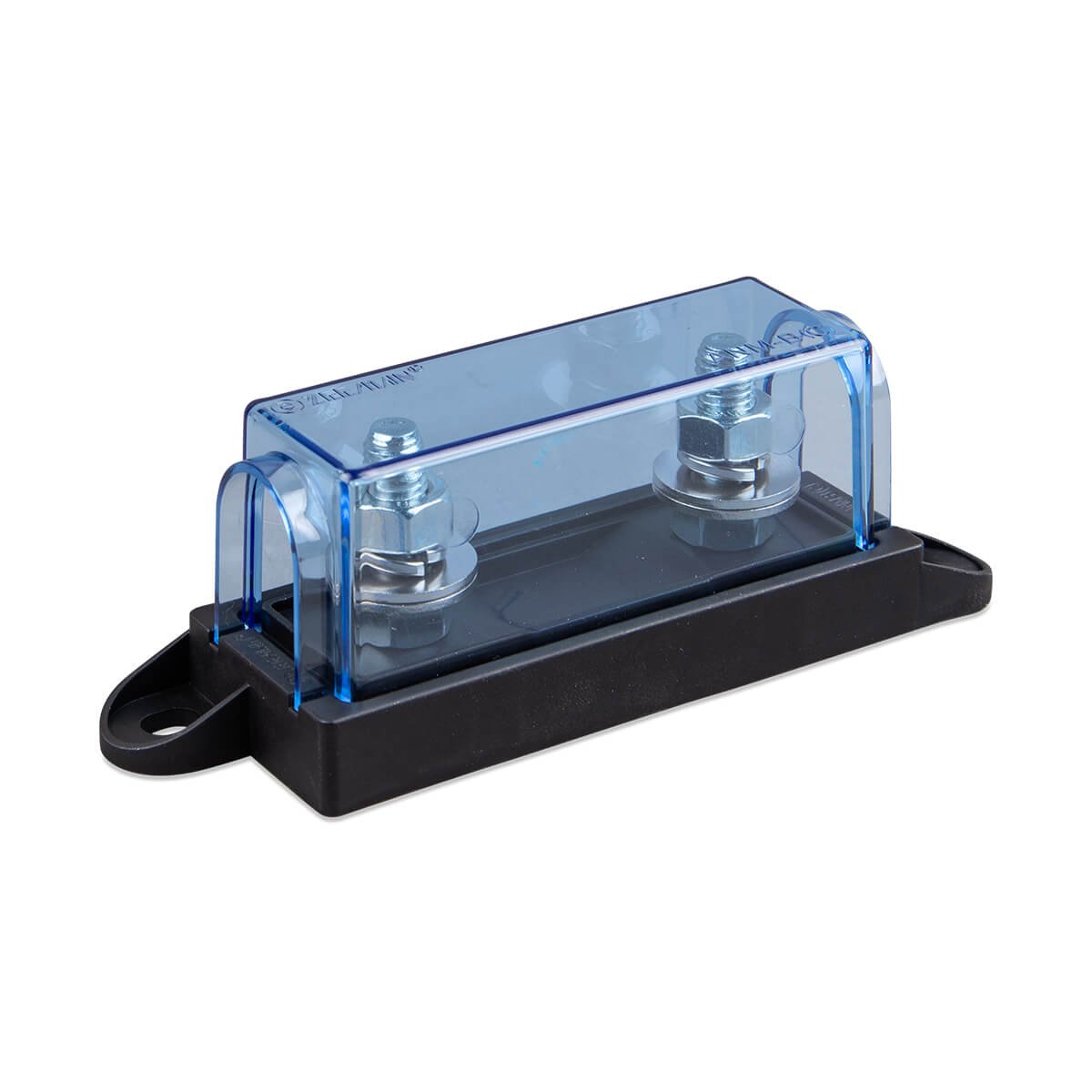

It’s only compatible with MEGA fuses

The most common frustration with the Lynx Distributor is that it only accepts MEGA fuses. Littlefuse and Victron manufacture MEGA fuses in ratings from 40A – 500A. 40A MEGA fuses are less common, and therefore often come at a premium.

Many high-spec systems looking to make use of a Lynx Distributor have a relatively small solar array. In this case, it’s common for a charge controller in a high spec campervan electrical system to have a 20A load, and only require a 30A fuse. Accordingly, connecting this to the Lynx Distributor can prove challenging.

One solution is to combine loads to a single fuse on the Lynx Distributor. One terminal with a 80A fuse could connect two 20A charge controllers, each with an inline 40A MIDI fuse.

The 80A fuse would protect the main cable, and the 40A fuses would protect the charge controllers. As a consequence, the total cost would increase as you require two additional MIDI fuses and MIDI fuse holders. In this instance, it may make sense to consider an alternative solution to the Lynx Distributor.

Most MEGA fuses are rated to 32V. Victron and Littlefuse do make 58V and 70V variants, but these start at 60A for Littlefuse and 125A for Victron. Therefore, the previous issues with fuse sizes may be more prevalent for 48V systems. Read more about the differences of 12V, 24V and 48V electrical systems in our DC system voltage article.

It only has one ground terminal

A bigger limitation of the Lynx Distributor is that it only provides one terminal to make ground connections to. A system with an inverter/charger, consumer unit and solar charge controller will need three ground connections, as well as a common chassis ground. Unfortunately, it’s not physically possible to fix this many connections to one terminal. So, it is necessary to also include a chassis ground busbar for cases where loads occupy all the negative terminals. This then allows just one connection to the Lynx Distributor.

Kirchhoff’s current law states that the current is equal at all points in a series circuit. As a consequence, the grounding busbar would need the same rating as the others. An alternative to using a busbar would be to connect all grounding connections to the vehicle’s chassis. But, it would likely prove difficult to make lots of connections to the chassis and end up using more cable.

How to wire a Lynx Distributor

Depending on its use case, the best way to connect the Lynx Distributor will be different. These wiring diagrams show examples of how to best incorporate a Lynx Distributor into your electrical system.

How to wire a Lynx Distributor to a battery pack

This wiring diagram shows an example where the Lynx Distributor is the only part of the Lynx Distribution system used.

The connected SmartShunt battery monitor takes the place of the Lynx Shunt in the system for a more cost-effective approach.

The battery bank fuse lies as close to the batteries as possible, making it very difficult for a short to damage the batteries.

The cables entering the Distributor from the bottom would then connect to various sub-systems (e.g. an inverter/charger).

How to earth a Lynx Distributor

Because the Victron Lynx Distributor only has one terminal for earth connections, most electrical systems will require a separate earth busbar.

You can connect the earth terminal on the Distributor to a busbar. This is in turn connects to earth as well as the grounds of various sub-systems within the electrical system.

Alternatively, you can earth each sub-system to the chassis individually and then make a single earth connection from the Lynx Distributor.

How to connect more than 4 subsystems to a Lynx Distributor

Despite only having four fuse holders, there are a few ways to connect more loads to the Lynx Distributor.

This first method is useful if you don’t need to connect the Distributor to another Lynx product. Here, the end terminals make a fifth connection. These are normally reserved to connect a Lynx Shunt or BMS.

Hence, you need a separate inline MIDI or MEGA fuse holder, as this position was not intended for a load connection.

In some cases, the smallest MEGA fuse will be too large to protect a component. A common workaround is to connect two components to one terminal using a single line, as shown below.

You would then rate the MEGA fuse for the combined maximum current draw, and fuse each component individually after the cable splits.

You can bolt multiple Lynx Distributors together in cases where you require more than five connections, or the end terminals are occupied by another Lynx component.

Victron specifies that you can connect a maximum of four Lynx Distributors together. However, the actual safe number depends on the constant current flow across them, so make sure you run the calculations first!

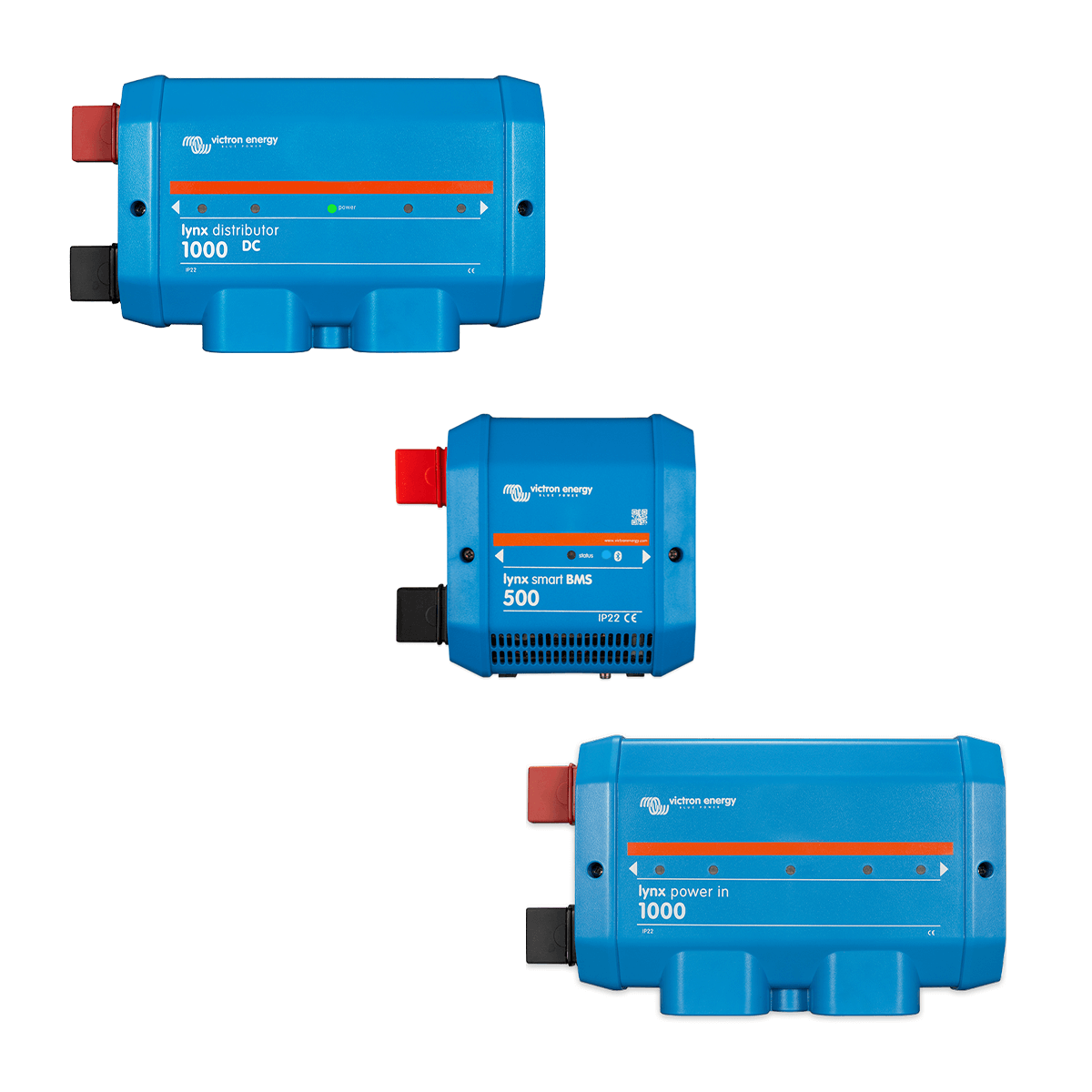

The Victron Lynx Ecosystem

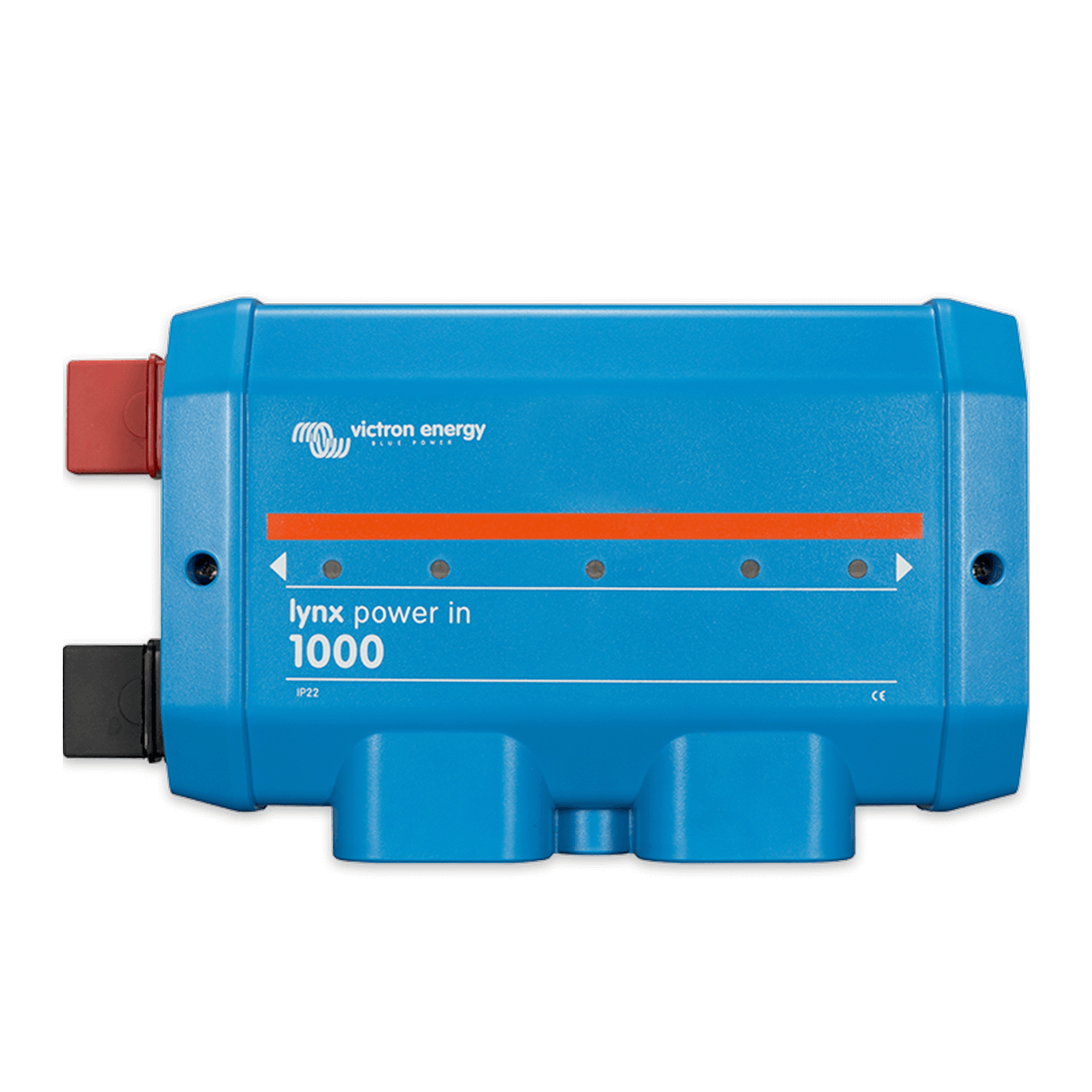

The Lynx Distributor is one of four products in the Lynx ecosystem. The other products consist of the Lynx Power In, the Lynx Shunt and the Lynx Smart BMS.

You can use them standalone, or bolted together to fit your system’s needs. The following diagram shows an example of a Lynx distribution system with a Lynx Power In, Lynx Shunt and Lynx Distributor.

Another Lynx Distributor can replace the Power In to fuse each string of series connected batteries. This would protect the batteries from a short between the Power In busbars if you had not fused the batteries before this point. Aditionally, for the Smart BMS or Shunt to function correctly, the battery bank must always be to the left and the DC loads to the right.

The Victron Lynx Power In

The Lynx Power In is essentially a Lynx Distributor without the fuse holders or indicator LEDs. It provides a point to connect multiple leisure batteries together in parallel, creating a large battery bank.

It’s best utilised in systems with lots of batteries and a high system voltage, as shown in the diagram below. Here, the Power In connects multiple strings of series connected 12V batteries. This creates a series-parallel 48V battery bank.

The cables connecting each series ‘string’ of batteries must be the same length when connecting batteries in parallel. In effect, this ensures that the system draws the same amount of power from each battery so you don’t damage them.

The Lynx Power In is often used in systems with 24V or 48V series parallel battery banks. It’s also perfectly acceptable to wire battery banks together with cable rather than busbars, so even in this instance, a Power In isn’t strictly necessary. The Power In isn’t usually needed in a campervan electrical systems as 24V and 48V systems are rare.

‘Hacking’ the Lynx Power In to become a Lynx Distributor

A more common use case for the Victron Power In is to hack it and ‘turn it into’ a Lynx Distributor. You can add bolts to hold MEGA fuses as they share the same casing and busbars. This results in the same functionality as the Distributor, just without the fuse status indicators. We won’t go into how to do this, but there’s plenty of information online to help you.

After buying the required hardware, you’ll have saved around £50 over buying the Distributor. So, you just need to decide if it’s worth the bother! A small perk of this hack is that you can choose which of the connections to fuse at the terminal. This is useful for components where a MEGA fuse would be too large, and allows a MIDI fuse holder to be installed externally instead.

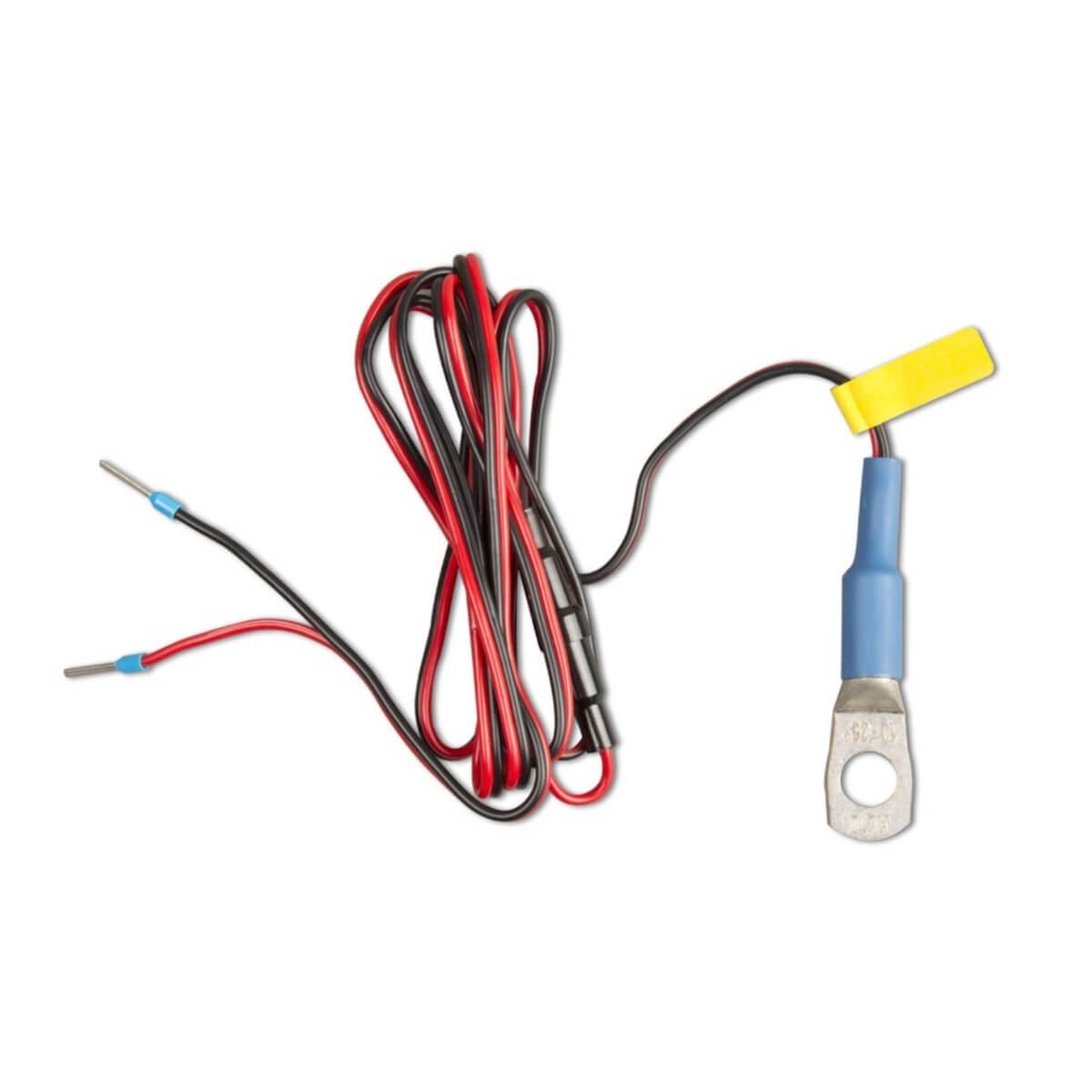

The Victron Lynx Shunt VE.Can

The Lynx Shunt is a battery monitor intended for you to fix between a Lynx Power In and a Lynx Distributor. It two 1000A busbars that you can bolt to both the Lynx Power In and Lynx Distributor, and an ANL (or CNN) fuse holder. Victron intends this fuse to act as the main system fuse. However, it’s important for this to be as close to the batteries as possible, so a closer inline MEGA fuse may be more appropriate.

Like the Victron SmartShunt and Victron BMV battery monitors, it takes readings of the battery voltage, current draw and many other factors. It can combine these to output a State of Charge (SoC) reading of the battery bank.

Unlike most other Victron battery monitors, the Lynx Shunt doesn’t have Bluetooth connectivity. So, you need to pair it with a Colour Control GX or Cerbo GX to receive data.

Alternatively, the 1000A Victron SmartShunt is a cheaper option, at £140 less than the Lynx Shunt. Therefore, if you’re trying to keep to a budget, this non-modular option makes sense. But, for those looking for the easy route to a neat and tidy system, the modular Lynx Shunt is a useful addition to the ecosystem.

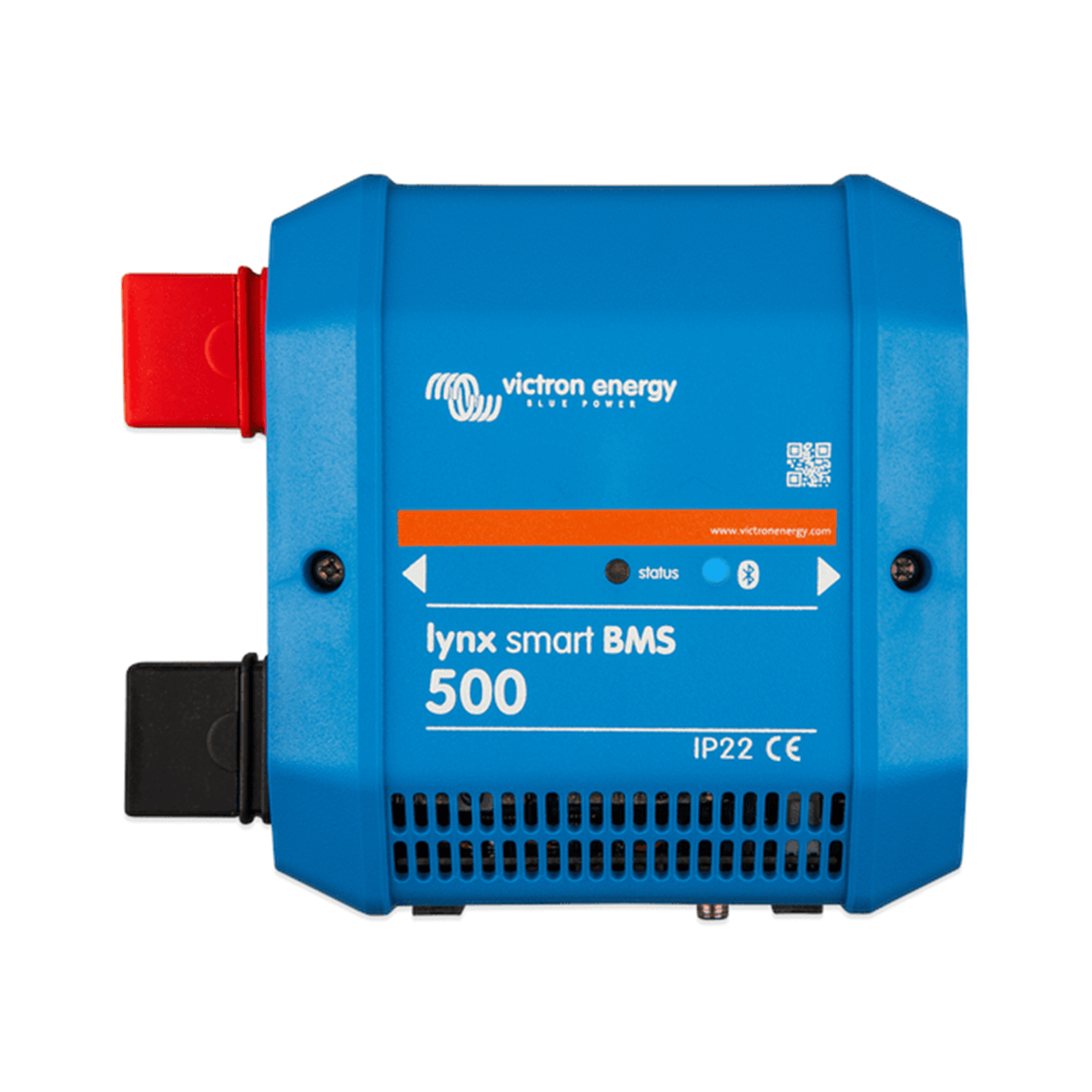

The Victron Lynx Smart BMS

The final product to bolt into your Lynx Distribution system is the Victron Lynx Smart BMS. It monitors, manages and protects Victron Smart lithium batteries, but isn’t compatible with other battery brands.

Like the other components in the ecosystem, it contains two busbars, although this time only rated to 500A. So, bear this in mind if you were intending to use the 1000A current rating of the Distributor.

Additionally, a battery management system (BMS) controls a contactor (high current relay) positioned on the positive busbar. This can quickly break the circuit to protect the batteries.

Like with the Lynx Shunt, it includes a 500A shunt, used for battery monitoring. Conveniently, you can monitor the Smart BMS through a connected GX device or via Bluetooth to the VictronConnect app.

You need a battery management system (BMS) to protect and manage the cells within a lithium leisure battery. Manufacturing techniques mean that cells have a different State of Charge – a measure of the charge in a cell in respect to its capacity.

The BMS balances the SoC between the cells, preventing damage from under or over charging and maximising the battery’s capacity. BMS’s also monitor and manage the operating voltage, current and temperature of the cells to ensure they are kept within the safe operating area (SOA). This is a range of currents, voltages and temperatures that a battery can safely operate within.

Most lithium-ion batteries, such as those from TN Power or Fogstar, have an inbuilt BMS. In comparison, Victron’s do not. So, if you’ve building an all blue system, you’ll need to fork out for a separate Victron BMS such as this Lynx Smart BMS, which are only compatible with Victron batteries.

You need to connect a Lynx Shunt or Lynx Smart BMS to use the Status LEDs

You need either the Lynx Shunt or the Lynx Smart BMS, to power the fuse status LEDs on the Lynx Distributor. Luckily, a quick google will provide a simple ‘hack’ to power status LEDs without a Lynx Shunt, and is worth considering if you want to use a different battery monitor.

Unfortunately, to monitor the fuse status on the Victron Connect app, you will need the Smart BMS. As this is only compatible with Victron lithium batteries, if your system contains another type of battery, there’s no way to connect your Lynx Distributor to your phone!

Closing thoughts

The Lynx Distributor only becomes more cost-effective than traditional busbars when your electrical system draws currents over 250A. Regardless, for many of those with a smaller system, the benefits of an all-in-one, modular system with neat cable routing and compatibility with the Victron Connect app may make the extra cost for worth it.

If you decide that a Lynx Distributor is right for you, you can save on the other components by connecting your battery bank and a shunt directly to it. You should only really consider adding a Power In to the mix if you want it to consolidate a large series-parallel 48V system and need the 1000A current capacity.

The Lynx Shunt and Smart BMS are very much luxury items. Although useful products that fit nicely into the modular system, more cost-effective options exist for monitoring and controlling your battery banks!

Campervan electrics leaving you confused?

Victron Lynx Distributor Frequently Asked Questions

-

The Victron Lynx Distributor is a DC busbar unit that provides a point for loads in an electrical system to securely connect to the battery bank. It contains a positive and negative busbar, each rated to 1000A, and four MEGA fuse holders. Internal cable routing means the result is more organised and compact than using traditional busbars. A series of LED lights indicate when a fuse has blown, if connected to a Lynx Shunt VE.Can or Smart BMS. It can also relay this data to the Victron Connect app (Smart BMS only).

-

The Lynx Distributor isn’t rated to 2000A because it has two 1000A busbars. Because the busbars are connected to the battery in series, they each have to carry the full circuit load. For this reason, you can’t add the current capacities of each busbar together, and it remains at 1000A.

-

The Victron Lynx Distributor is only compatible with MEGA fuses. Victron and Littlefuse manufacture these in 40A – 500A ratings. Unfortunately, ANL and MIDI fuses are incompatible with the Lynx Distributor. Therefore, you can only use fuses rated to 40A or higher.

-

The Lynx Distributor and Lynx Power In share the same housing, but the Power In does not contain fuse holders or indicator LEDs. Victron intended the Lynx Distributor to connect loads such as an inverter/charger or a solar array to the battery bank. On the other hand, they designed the Power In to create a higher voltage system by connecting batteries in parallel. The Power In can be ‘hacked’ to function similarly to the Distributor, you just need to decide if the effort is worth the cost difference.

-

The alternative to using the Lynx Distributor is to use two separate busbars and individual fuse holders. For most systems with a maximum current draw under 250A, this will be more cost-effective. It also gives more freedom with fuse sizing. However, for some, the additional cost and fuse limitations are worth the organisational benefits of the Lynx Distributor.

Well written and really informative, thank you.

Thank you, we’re glad you found the article useful!

Super easy to understand cheers. So i could effectively use bus bars to connect to battery charger from shore power and a fuse box that’s currently direct from leisure battery and just have one positive and negative running to the leisure battery (as it sits on other side of van)?

Yes, exactly, it helps to rationalise the setup, improve contact at connections and reduces cable lengths. This not only makes for a safer, more efficient system but also keeps everything tidy!